ABOUT US

Stresscrete Pole Corporation (SPC) was established and incorporated in 1998 by a group of young idealistic Filipino professionals with the prime objective to "bring quality concrete poles to the countryside at very reasonable price". This objective supports the government goal in bringing cheaper electricity to the Filipino families and the Industrial communities even in the most remote barangays in the provinces. In fact Stresscrete has been very active participant in the "O-llaw Projects" of the government.

To date, Stresscrete has more than 10 years experience in the concrete pole manufacturing business in the country. Supplying thousands of quality concrete poes to the countryside. Providing technology assistance to various electric cooperatives, energy providers and telecommunication companies. Aside from supplying concrete poles, Stresscrete also provides emergency assistance to its customers as equipment and personnel in times of calamity.

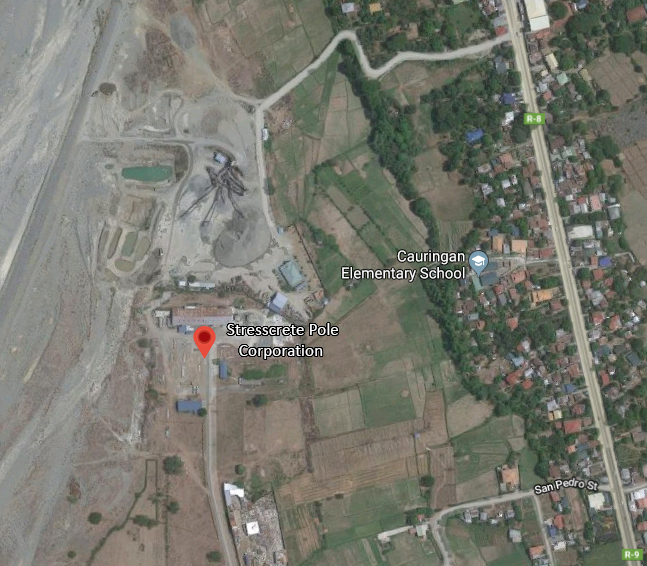

The plant is located in Barangay Cauringan, Sison Pangasinan, covering a total are of 70,000 square meters. It is strategically located in the heart of Luzon intended to have closest proximity to delivery points at different areas. Its production building has six production lines designed with modern production technology equipment and testing facilities to produce a maximum of 20,000 quality concrete poles annually.

Stresscrete Pole Corporation is operated by a team of professional managers and experienced engineers backed up by 50 strong dedicated highly trained production employees. The team maintains high quality tradition conforming to the local and international specification standards.

Within the team is the Stresscrete engineering group It provides the necessary design of the pole using computerized design program for concrete poles. The group also provides experienced personnel that fabricates moulds for each design requirement. These men are only one of the few fabricators in the philippines that can fabricate moulds with extreme accuracy.

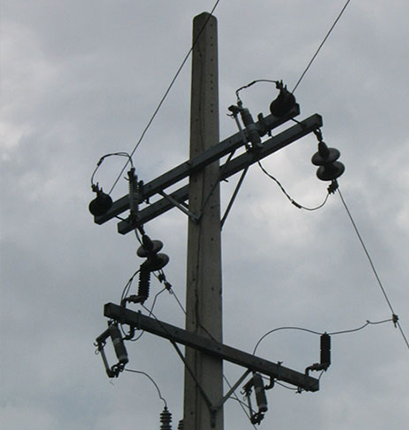

Unlike other concrete poles such as the hollow cored round centrifugal and octagonal, Stresscrete poles was designed to be solid. It is also known as the "I-SECTION TYPE" or sometimes called as the "I_BEAM TYPE". It is so called because its cross section is shaped like letter I or H. This solid design is what makes it at high yield strength capacity at minimal sectional area. Engineered shape to provide better ground embedment stability. Aside from the consistent monitoring on the quality of production materials each pole type is randomly break load tested regularly to guarantee they meet the required specifications ath the time of delivery. It is so versatile that it can accommodate different types of hardware originally designed for other pole shapes. Other end users even find it more cost effective due to its solid and flat surface design which minimize accessory requirements.

"I" Section Pole Types

| Size/Class | Breaking Load | Size/Class | Breaking Load |

|---|---|---|---|

| 25 ft class 7 | 500 | 35 ft class 3 | 1360 |

| 30 ft class 7 | 500 | 35 ft class 3 | 1680 |

| 30 ft class 5 | 860 | 40 ft class 4 | 1080 |

| 30 ft class 5-A | 1000 | 40 ft class 3 | 1360 |

| 30 ft class 3 | 1360 | 40 ft class 2 | 1680 |

| 35 ft class 7 | 500 | 45 ft class 4 | 1080 |

| 35 ft class 5 | 860 | 45 ft class 3 | 1360 |

| 35 ft class 5-A | 1000 | 45 ft class 2 | 1680 |

Comparison of Electric Poles

| Type | Concrete Pre-stressed | Wood Treated | Steel Galvanized |

|---|---|---|---|

| Useful Life (yrs) | Over 35 | 8-10 | 15-20 |

| Maintenance | Free | Needed | Needed |

| Fire Resistance | Yes | No | Partially |

| Weight | Medium | Medium | Light |

| Load Capacity | Same | Same | Same |

| Ground Contamination | No | Yes | No |

| Corrosion | No | No | Yes |

| Major Sources | Domestic | Imported | Imported |

| Aesthetic | OK | OK | OK |

| Local Content | 85% | 0% - 80% | 20% |

| Hardware-Pole Top | NEA Standard | NEA Standard | Special |

| Crossarm | Same | Same | Special |

Comparison of “I” Section, Round and Octagonal Concrete Pole

| “I” SECTION | ROUND | OCTAGONAL |

|---|---|---|

| Can be pre-holed based on users requirement and still meet the desired strength | Can be pre-holed but will lessen the desired strength | Same as round poles except instead of spinning, pencil vibrator is used, however due to the structure of the mould with mandrill in the center, vibrator cannot penetrate the lower portion of the mould thus thick plastering is required to hide massive honeycomb/air bubbles |

| Bolt can be used instead of clamps for assemblies | Clamps has to be used for assemblies thus contributing more accessories to the bulking inventory of materials being maintained | |

| Can be designed up to the highest class (class 1) to suit designer’s requirement for every particular situation and assemblies, high class poles can be erected with a longer span/distance between poles | Difficult to manufacture for higher class pole because of density of reinforcement where coarse aggregates can no longer pass thru. | |

| Stresscrete poles are pre-holed based on NEA hole requirement and for all possible configuration of assemblies | A Common feature | |

| Aesthetic | Crack usually occur at the seams | |

| Life-over 35 years | Difficult to handle due to its hollow design, subject to more breakage | |

| Low cost | Spinning process disadvantage is that coarse aggregates sets at the outer portion of the pole during high speed spinning while finer aggregates settle at the inner portion, causes the pole to weaken | |

| Easier to handle | ||

| Ultimate strength up to 2,040 kgs |

WHY CHOOSE STRESSCRETE

Stresscrete Electric Poles are specially and structurally engineered for rural electrification and telecommunication lines.

The product is pre-stressed, pre-tensioned rectangular concrete poles of “I” section shape specially engineered and designed for Philippine market. This product, like wood and steel poles, are support structures for overhead power conduction and equipment.

Compared to wood and steel materials, pre-stressed concrete has for over 30 years been proven to be the best materials available for distribution poles and lighting standards.

2. Concrete power poles are more durable and resistant to weather and termites.

3. Concrete power poles do not contain any chemicals that will leech to the ground like those of wood poles.

4. Pre-stressed poles are resilient and will recover from effects of a great degree of overload than any other structural materials. They remain crack-free at working loads.

5. In addition to their long term cost benefits due to their durability, stresscrete concrete power pole about the same or lower than wood and are definitely more cost efficiently than steel.

6. Stresscrete concrete power poles will be available in strategic location in the Philippines. Faster and "just in time" delivery are possible thereby reducing carrying cost. Faster sourcing is critical during calamities and major line damage.

2. Long lifespan, high strength and wide range of sizes/classes

3. Heat/Fire Resistant and Corrosion Free

4. Minimal use of hardware clamps/braces

5. Pre-installed epoxy dipped galvanized grounding clips

6. Engineered shape for better ground foundation, transport, handling and maintenance

7. Quality tested, reasonable priced and prompt delivery

PROJECTS

Gallery

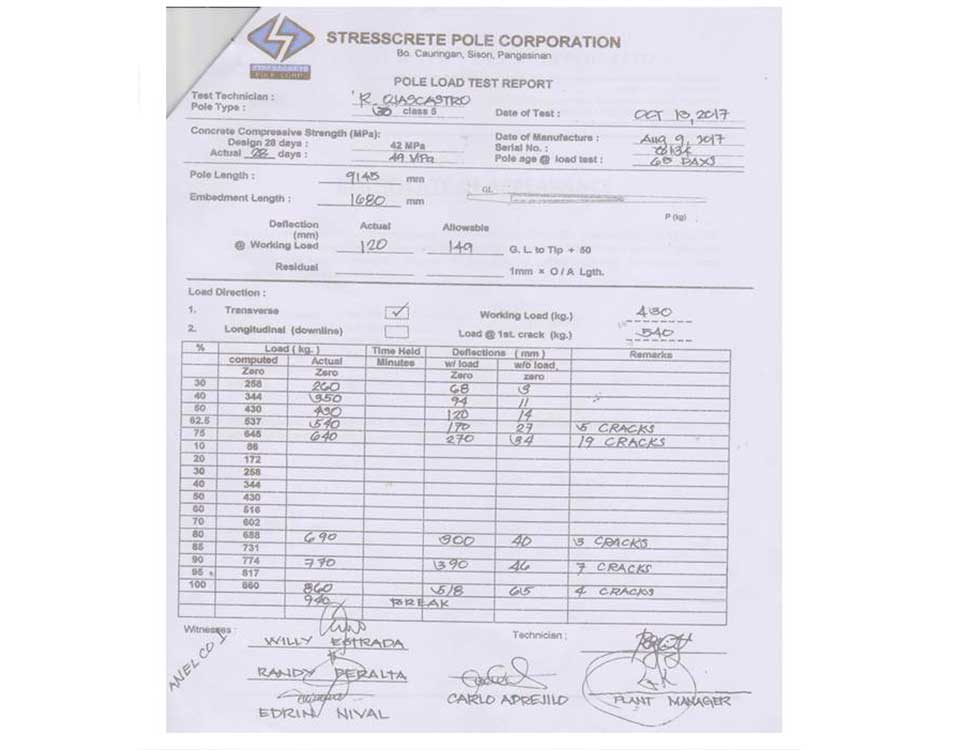

Product Destruction Test Result

Pole Testing CAGELCO II, ZAMECO I and PANELCO I

Crossarm Assembly

Pole Erection

CONTACT INFO

MANILA OFFICE

Suite 809 Richmonde Plaza, No. 21 San Miguel Avenue cor Lourdes Drive, Ortigas Center, Pasig City, 1600

Telephone: (02) 8633 5891

Email: videt_pf@yahoo.com

PLANT SITE

Km. 208 McArthur Hway, Bgy. Cauringan, Sison, Pangasinan

Telefax: (075) 567 6117

Fax: (075) 567 6117

Mobile: 0917 839 9992 / 0918 920 9179

Email: stresscrete.1998@gmail.com / spc_sison@yahoo.com